Concrete floors, while durable, often lack the visual appeal many homeowners and businesses desire. Fortunately, epoxy flakes offer a transformative solution that combines durability, functionality, and style. At Gresham Concrete Coatings, we specialize in epoxy flake flooring systems designed to turn plain concrete into eye-catching, slip-resistant surfaces perfect for garages, basements, commercial spaces, and more.

What Are Epoxy Flakes?

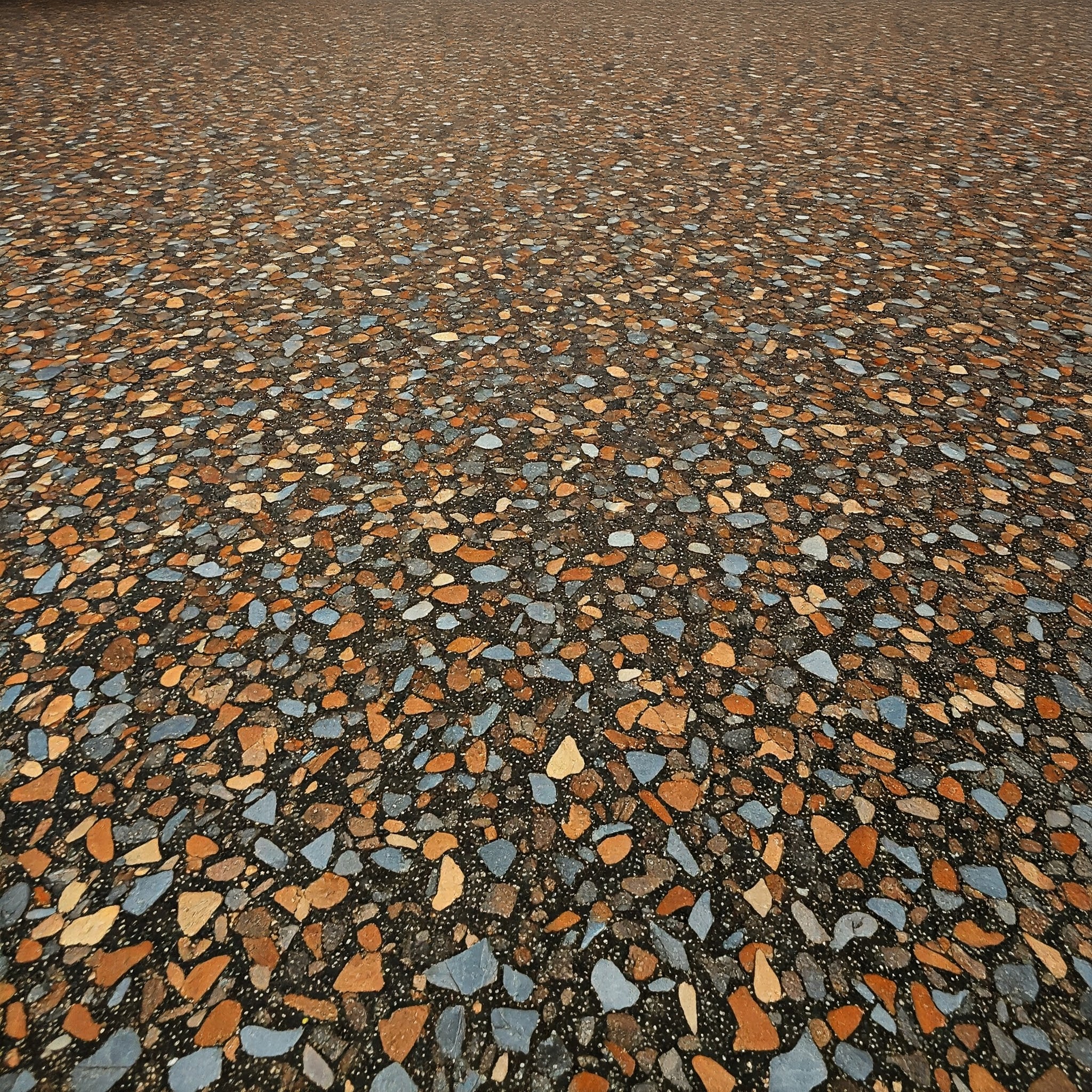

Epoxy flakes, also known as decorative vinyl chips or flakes, are small, colorful pieces embedded in a layer of epoxy. These flakes come in various sizes, colors, and finishes, allowing for a fully customized design. Once the epoxy cures, the flakes create a textured, multi-dimensional surface that enhances the floor’s appearance while improving its functionality.

| Factor | Key Considerations | Why It Matters |

| Aesthetic Appeal | – Customizable color combinations and finishes.

– Various flake sizes for texture variation. |

Enhances the visual appearance, offering a personalized style to suit any space. |

| Durability | – Highly resistant to wear, impact, scratches, and stains.

– Ideal for high-traffic areas and heavy equipment. |

Ensures long-lasting performance, even in demanding environments. |

| Slip Resistance | – Textured surface improves grip.

– Reduces slip hazards, especially in wet or greasy areas. |

Increases safety, making it perfect for spaces prone to moisture or spills. |

| Maintenance | – Low-maintenance due to non-porous surface.

– Easy to clean with regular sweeping and mopping. |

Saves time and effort, keeping floors looking new with minimal upkeep. |

| Cost-Effectiveness | – Affordable compared to other flooring options.

– Long lifespan (10-15 years or more) offers a strong return on investment. |

Offers a budget-friendly solution without sacrificing quality or aesthetics. |

| Customization | – Choose from a wide range of colors, flake sizes, and finishes.

– Mix and match to create a unique look. |

Provides flexibility to match personal preferences or business branding. |

| Installation Time | – Typically takes 2-3 days for completion, including curing time.

– Minimal disruption to daily activities. |

Quick turnaround for minimal downtime during the installation process. |

| Suitability for Heavy Loads | – Durable enough for garages, workshops, and commercial spaces.

– Resists damage from heavy machinery or equipment. |

Ideal for high-impact spaces requiring robust flooring. |

| Longevity | – Floors last up to 15 years or more with proper care.

– Resistant to fading, cracking, and peeling. |

Long-term value with a lasting, durable finish. |

| Outdoor Use | – UV-resistant topcoat for outdoor areas.

– Suitable for pool decks, patios, and more. |

Extends the versatility of epoxy flakes for outdoor applications. |

Benefits of Epoxy Flake Flooring

1. Enhanced Aesthetic Appeal

Epoxy flakes add texture, color, and depth to otherwise dull concrete surfaces. Whether you prefer subtle tones or bold patterns, the customizable nature of epoxy flake systems ensures your floor matches your style.

2. Increased Durability

Epoxy flake floors are highly resistant to wear and tear, making them ideal for high-traffic areas. The epoxy coating protects against impacts, scratches, and stains, ensuring your floor looks great for years.

3. Improved Safety

The textured surface provided by epoxy flakes enhances slip resistance, making it a safer option for areas prone to spills or moisture, such as garages, pool decks, and kitchens.

4. Low Maintenance

Epoxy flake floors are non-porous, making them easy to clean and resistant to dirt, grease, and spills. A simple sweep and occasional mop are all that’s needed to maintain their shine.

5. Cost-Effective Solution

Compared to replacing concrete or installing other flooring materials, epoxy flakes offer a budget-friendly way to rejuvenate your floor while adding value to your property.

How Gresham Concrete Coatings Transforms Concrete with Epoxy Flakes

At Gresham Concrete Coatings, we take a meticulous approach to epoxy flake flooring to ensure flawless results. Here’s how we do it:

1. Surface Preparation

Proper preparation is the foundation of a successful epoxy flake installation. We clean, grind, and repair the concrete surface to ensure the epoxy adheres perfectly.

2. Epoxy Base Layer Application

A high-quality epoxy base coat is applied evenly to create a durable foundation for the flakes. This layer also determines the overall color of the floor.

3. Flake Broadcasting

While the base coat is still wet, the epoxy flakes are generously broadcast across the surface. This step ensures even coverage and the desired level of texture.

4. Topcoat Application

Once the flakes settle and the base coat cures, a clear topcoat is applied to seal the surface. This topcoat enhances the floor’s durability, shine, and resistance to wear.

Where Epoxy Flakes Work Best

Epoxy flake flooring is versatile and suitable for a variety of spaces:

- Garages: Adds durability and a polished look while resisting tire marks and oil stains.

- Basements: Transforms dark, plain spaces into inviting areas for relaxation or recreation.

- Commercial Spaces: Creates an attractive and professional atmosphere in showrooms, retail stores, and offices.

- Pool Decks: Provides a slip-resistant surface that stands up to water and UV exposure.

- Workshops: Handles heavy equipment and tools without showing signs of damage.

Customizing Your Epoxy Flake Floor

Epoxy flake systems offer endless design possibilities. Choose from various flake sizes, colors, and finishes to create a floor that reflects your style.

- Flake Sizes: From fine to coarse, select the size that suits your desired texture.

- Color Combinations: Mix and match colors to complement your space or branding.

- Gloss Levels: Opt for a matte, satin, or high-gloss topcoat for the perfect finish.

Frequently Asked Questions

1. What are epoxy flakes made of?

Epoxy flakes are typically made from acrylic or vinyl materials. They are lightweight, durable, and designed to bond seamlessly with epoxy coatings.

2. How long does it take to install epoxy flake flooring?

Most installations take 2-3 days, depending on the size of the area and curing times. Gresham Concrete Coatings ensures minimal disruption while delivering top-quality results.

3. Are epoxy flake floors easy to maintain?

Yes, epoxy flake floors are low-maintenance. Regular sweeping and occasional mopping with a pH-neutral cleaner are enough to keep them looking pristine.

4. Can epoxy flake floors handle heavy equipment?

Absolutely. Epoxy flake floors are highly durable and designed to withstand heavy loads, making them ideal for garages, workshops, and industrial spaces.

5. Are epoxy flake floors suitable for outdoor use?

Yes, epoxy flake systems can be used outdoors, such as on pool decks or patios. UV-resistant topcoats protect the surface from sun damage and discoloration.

6. Can I customize the color of my epoxy flake floor?

Yes, epoxy flake systems are fully customizable. You can choose from a wide range of colors and combinations to match your style or branding.

7. How long do epoxy flake floors last?

With proper installation and maintenance, epoxy flake floors can last 10-15 years or more, making them a cost-effective investment.

8. Are epoxy flake floors slippery?

No, the textured surface created by the flakes improves slip resistance, making epoxy flake floors safer than smooth concrete or traditional epoxy coatings.

9. What is the cost of epoxy flake flooring?

The cost depends on factors like the size of the area, the type of epoxy used, and customization options. Contact Gresham Concrete Coatings for a personalized quote.

10. Why choose Gresham Concrete Coatings for epoxy flake flooring?

Gresham Concrete Coatings combines expertise, high-quality materials, and exceptional customer service to deliver stunning and durable epoxy flake floors tailored to your needs.

Revitalize your dull concrete floors with epoxy flakes from Gresham Concrete Coatings. Contact us today to schedule a consultation and start your transformation!